Qaphela: Idatha kulesi sihloko ingeyereferensi kuphela

1. Izingxenye ze-rotor

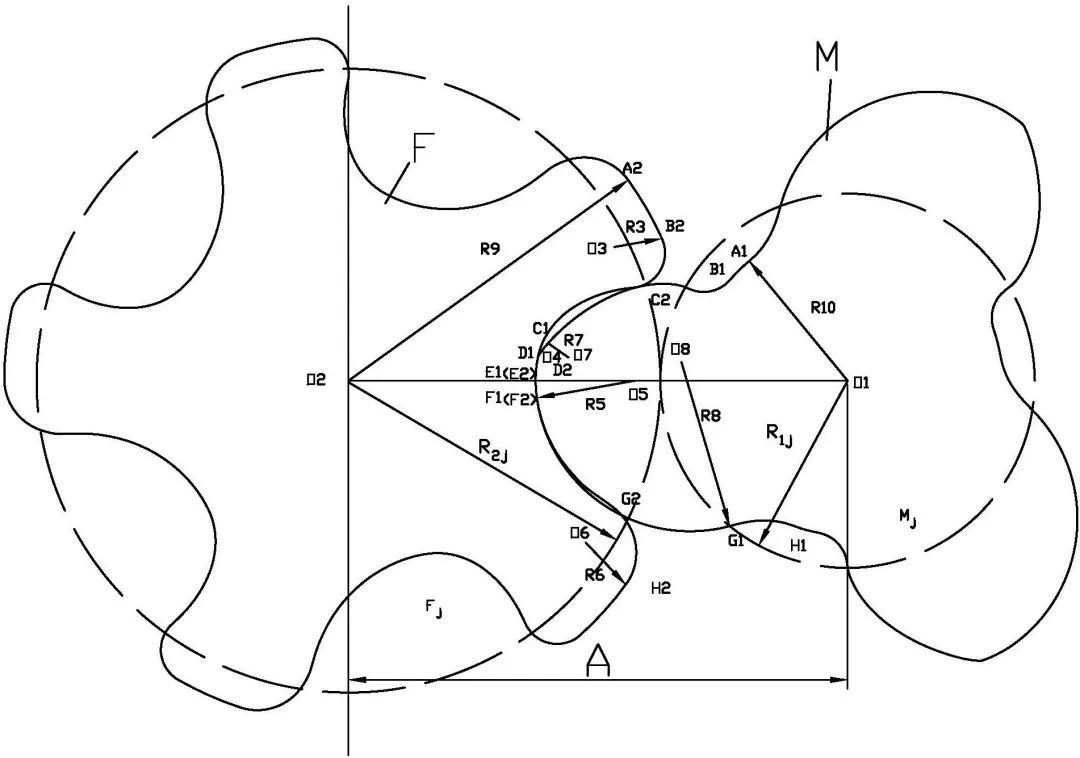

Ingxenye ye-rotor iqukethe i-rotor esebenzayo (i-rotor yesilisa), i-rotor eqhutshwa (i-rotor yesifazane), i-main bear, i-thrust bear, i-bearing gland, i-balance piston, umkhono we-balance piston nezinye izingxenye.

2. Izigigaba zephutha ezijwayelekile ze-yin ne-yang rotor

① Ukuguga nokuguga okujwayelekile

Ukugqokwa kobubanzi obungaphandle beziteshi zegiya ze-yin ne-yang;

Ukuguga okuvamile kwesilinda se-rotor.

② Ukulimala komshini okwenziwe umuntu

Ukuklwebheka kububanzi obungaphandle bemigudu yamazinyo e-Yin ne-Yang rotor;

Ukuklwebheka ku-cylinder ye-rotor;

Uhlangothi lokungena kwe-rotor kanye nesembozo sokuphela kokukhipha siyaklwejwa;

Ukugqokwa kwama-bearings okukhipha kanye nokukhipha kanye nokugqokwa kombuthano wangaphakathi wekhava eliphethe;

Gqoka ububanzi be-shaft endaweni yokufaka i-rotor;

Iziphetho ze-shaft ze-yin ne-yang rotor zikhubazekile.

③ Izingxenye ezijwayelekile ezilimele noma ezibhajwe

Ukuklwebheka kanye nokugxumela (ukuvala) phakathi kwamarotha eYin neYang;

Phakathi kobubanzi obungaphandle be-rotor nodonga lwangaphakathi lomzimba;

Phakathi kwe-exhaust end yobuso be-rotor kanye nesihlalo esiphethe i-exhaust;

Phakathi kwejenali ekupheleni kokudonsa kwe-rotor kanye nomgodi we-shaft womzimba;

Phakathi kwejenali ekugcineni kwe-exhaust ye-rotor kanye nomgodi we-shaft wesihlalo esithwala i-exhaust.

3. Imbangela yokwehluleka

① Into yesihlungi somoya ayishintshwa ngesikhathi, okuholela ekungenweni kahle komoya kanye nokuguga okubucayi kwerotha; ukusetshenziswa okuxubile kwamafutha okugcoba emikhiqizo ehlukene kuzovame ukuholela ekuxhumaneni nokugqoka kwe-rotor;

②Uhlobo lwamafutha e-compressor asetshenzisiwe alufanelekile noma alushintshwa ngesikhathi njengoba kudingekile. Ukungcola emafutheni kudlula izinga, okubangela imihuzuko ku-rotor nesilinda;

③ Izinga lokushisa lokukhipha umoya liphansi kakhulu ngesikhathi sokusebenza, okwenza umswakama kuwoyela negesi ube phezulu kakhulu. Ukusebenza isikhathi eside kuzokwenza ukuthi amafutha afakwe emulsify, okuholela ekusebenzeni isikhathi eside futhi ama-inlet kanye nama-exhaust end bearings ngeke agcotshwe ngokuphumelelayo ngesikhathi sokujikeleza kwejubane eliphezulu kanye nomthwalo osindayo. Ukulimala okushisayo kuzokwenza ukuthi i-rotor ibe intambo, ikhubazekile futhi ibambelele;

④Ukuguqulwa kwekhanda le-rotor drive end shaft ngenxa yokuvunyelwa kwe-meshing yegiya lokuhlanganisa idrayivu noma ukwehluleka kokuxhumeka kokhiye wegiya;

⑤ Ukulimala okungavamile okubangelwa ikhwalithi yokuthwala.

Ukungasebenzi kahle okungenhla kweair compressorsngokuvamile zibangelwa abantu. Emsebenzini wokulungisa nsuku zonke, inqobo nje uma izinqubo zokusebenza nokugcinwa zilandelwa ngokucophelela, ukwehluleka okungenhla kungagwenywa ngokuphelele.

Ngamafuphi, ijenali yokuncela kanye ne-exhaust end ye-screw compressor rotor isekelwa ama-bearings emzimbeni we-compressor kanye nesihlalo esiphethe i-exhaust ngokulandelana. Uma i-coaxiality yomzimba we-compressor, isihlalo esithwala i-exhaust, kanye ne-rotor kungenxa yokucutshungulwa kwemishini noma ukuhlangana, Uma izidingo zokuklama zingahlangatshezwana nazo, kuzoholela kalula emihumeni phakathi kwama-rotors, i-rotor nomzimba, i-rotor nokunye. izingxenye, noma i-rotor ibambeka. Ngokuvamile, imfuneko ye-coaxiality phakathi kwembobo ye-shaft kanye ne-rotor compression chamber ingaphakathi kwe-0.01 ~ 0.02mm.

Ukucaciswa phakathi kwezingxenye ekamelweni lokucindezela lei-screw compressorngokuvamile kukalwa ngocingo noma mm. Izingxenye ezisegunjini lokucindezelwa zifaniswa ngamandla. Uma inani lemvume eliklanyelwe lincane kakhulu, lihambisana nephutha enqubweni yokukhiqiza, i-rotor izolimala kalula. Ulimele noma ubhajwe. Igebe phakathi kwe-rotor nomzimba ngokuvamile liba ngu-0.1mm, futhi igebe phakathi kobuso bokuphela kwe-rotor kanye nesihlalo esiphethe i-exhaust ngu-0.05 ~ 0.1mm.

Ngesikhathi senqubo yokuhlukanisa i-i-compressor, ngoba ukuthwala kanye ne-rotor shaft kuhlanganiswe ngokuqinile, uma amandla okuhlakazeka makhulu kakhulu, azokwenza ukuguqulwa kwezingxenye kanye ne-coaxiality yezingxenye ngokwazo zizoncishiswa.

Ngemva kwei-compressorihlangene, kuyadingeka ukuhlola i-coaxiality jikelele yomhlangano. Uma i-coaxiality ingaphandle kokubekezelelana, izobangela imihuzuko phakathi kwezingxenye noma i-rotor izobanjelwa.

4. Izingozi kanye nokutholwa komonakalo we-rotor

Ngesikhathi sokusebenza okujwayelekile kwe-I-air compressor,uma umsindo ongajwayelekile, ukudlidliza okwenyukayo, izinga lokushisa eliphezulu lesikhathi eside, noma ukugcwala okukhona manje, kufanele kuvalwe ukuze kuhlolwe ngokucophelela. Kufanele ugxile ekuhloleni ukuthi ama-air compressor bearings awonakele yini nokuthi ukuphela kwe-rotor shaft kukhubazekile.

Uma umonakalo kuma-rotor-end bearings ungabonakala ngesikhathi futhi umshini uvaliwe ngokushesha, ama-bearings ngeke ashise futhi abambelele, futhi izingxenye ezinkulu zemishini ngeke zilimale.

Uma umonakalo ekuthwaleni kokuphela kwe-rotor awukwazi ukutholwa ngesikhathi futhii-compressor yomoyaisebenza isikhathi eside, ukungqubuzana nokushelela kuzokwenzeka phakathi kwesiyingi sangaphakathi se-bearing kanye nendawo yokufaka i-rotor. Ezimweni ezimbi kakhulu, indawo yokuthwala i-rotor izoba luhlaza okwesibhakabhaka, i-roughened futhi ibe mncane, noma ukuphela kwe-rotor kuzovela. Umbuthano wangaphakathi wokuthwala ikhava unamathele, okwenza ukuthi indingilizi yangaphandle ye-bearing ijikeleze, okwenza imbobo yokuthwala yekhava yokugcina ikhule noma iphume nxazonke. Kungase kwenzeke ngisho nokuthi umonakalo othwalayo ubangela ngokuqondile ukuthi i-rotor iguqulwe ngaphansi kwesenzo samandla aphezulu, ibhubhise i-rotor coaxiality.

Ukuhlolwa kwama-yin nama-yang rotor ngokuvamile kuncike ekugugekeni nasekuklwebeni kwe-rotor. I-meshing wear yayo akufanele ibe ngaphansi kuka-0.5mm-0.7mm ububanzi. Indawo eklwetshiwe akufanele ibe nkulu kuno-25mm², ukujula akumele kube kukhulu kuno-1.5mm, futhi ukungahambi kahle komkhawulo we-rotor shaft akumele kube kukhulu kuno-0.010mm.

Uma udinga ukuthenga i-compressor yomoya, i-kaishan brand air compressor yethu ingaba yisinqumo sakho esihle. Nalu ulwazi lokuxhumana:

Wendy

E-Mail: wendy@shanxikaishan.com

Inombolo Yocingo/WhatsApp: +86 18092196185

Isikhathi sokuthumela: Oct-19-2023